Raising the BAR

- Our highly qualified and proficient inspectors have raised the bar by strictly adhering to our client requirements & specifications and also to the global standards of inspection, ensuring that all our processes and products are compliant with API Specification Q1 and ISO 9001 requirements.

- We utilize the Gage Maker MIC TRAC MT 4000 calibration and gauge systems ensuring great accuracy, repeatability, and reproducibility to yield the precision that can be trusted.

- We have a strong team of 25+ trained & competent professionals exclusively for Quality Control & Quality Assurance activities.

25+

Trained Inspectors

100%

Inspection of all parts

500+

Working Gauges

2

CMMs

METALLURGICAL Lab

Our metallurgical lab ensures the quality of all our heat-treated and case-hardened components and is equipped with the following inspection capabilities:

- Hardness Testers

- Rockwell (Zwick Roell Make)

- Brinell (King Tester Make) Hardness Tester

- Micro Vickers’ Hardness Tester

- Leeb Hardness Tester

- Ultrasonic Contact Impedance Tester (UCI)

- GE MIC20 / Krautkramer Tester

Measuring Lab

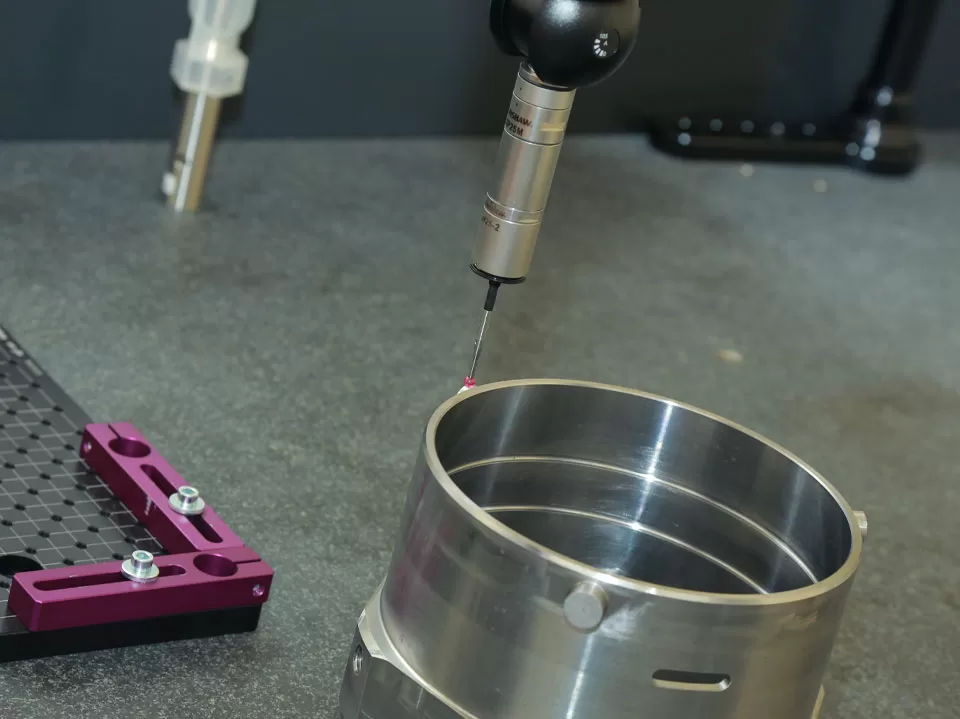

CMM Inspection Capability

PTMF uses the latest technology in Coordinate Measuring Machines (CMM) which can accommodate complex structure and measurements up to 900mm B x 2000mm L x 800mm H.

PTMF also employs the use of quality instruments such as profile projectors, surface roughness measuring devices, digital height gauges, thread gauges & several other precision quality instruments for In-process and final inspection.

We use the latest technology in CMM which can accommodate complex structure and measurements.

We have access to two CMMs:

- Aberlink CMM (640 mm x 600 mm x 500 mm)

- Mitutoyo CRYSTA – Apex V 9106 Machine – (900 mm x 2000 mm x 800 mm)

Our instrument repertoire consists of:

-

Profile Projectors

-

Surface Roughness Testers

-

UT Gauges

-

Digital Height Gauges

-

Thread Gauges

-

Conventional Inspection Methods